CONVEYORS

Tracks of various complexity can be built and modified quickly and easily, thanks to a structure consisting of standard and interchangeable elements.

Modularity also allows the system to be modifiable and expandable after time, following proper and adequate technical evaluation. The track can develop at varying heights via upward and downward curves, thanks to the ability of the biplanar chain to articulate on the vertical plane as well. Transport by hanging is particularly suitable for the surface finishing industry, as the system gives you complete access to all sides of the items being processed.

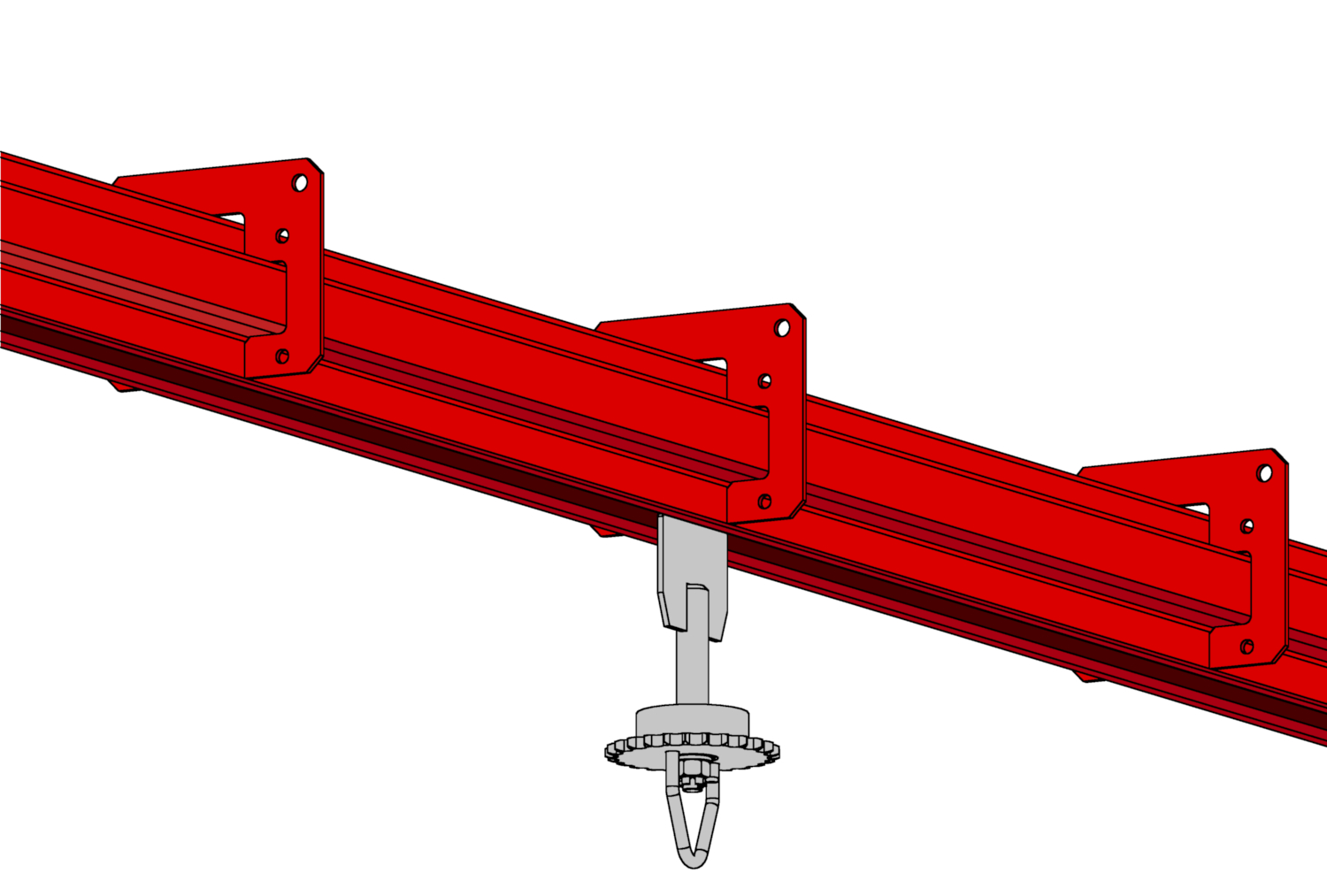

Single rail

The single rail overhead conveyor allows medium/light loads to be moved along courses consisting of both straight and curved sections. Parts are hung on the processing line by means of hooks attached to the chain and following a closed, continuous path.

Would you like to learn more about the single rail?

Double rail / Power & Free

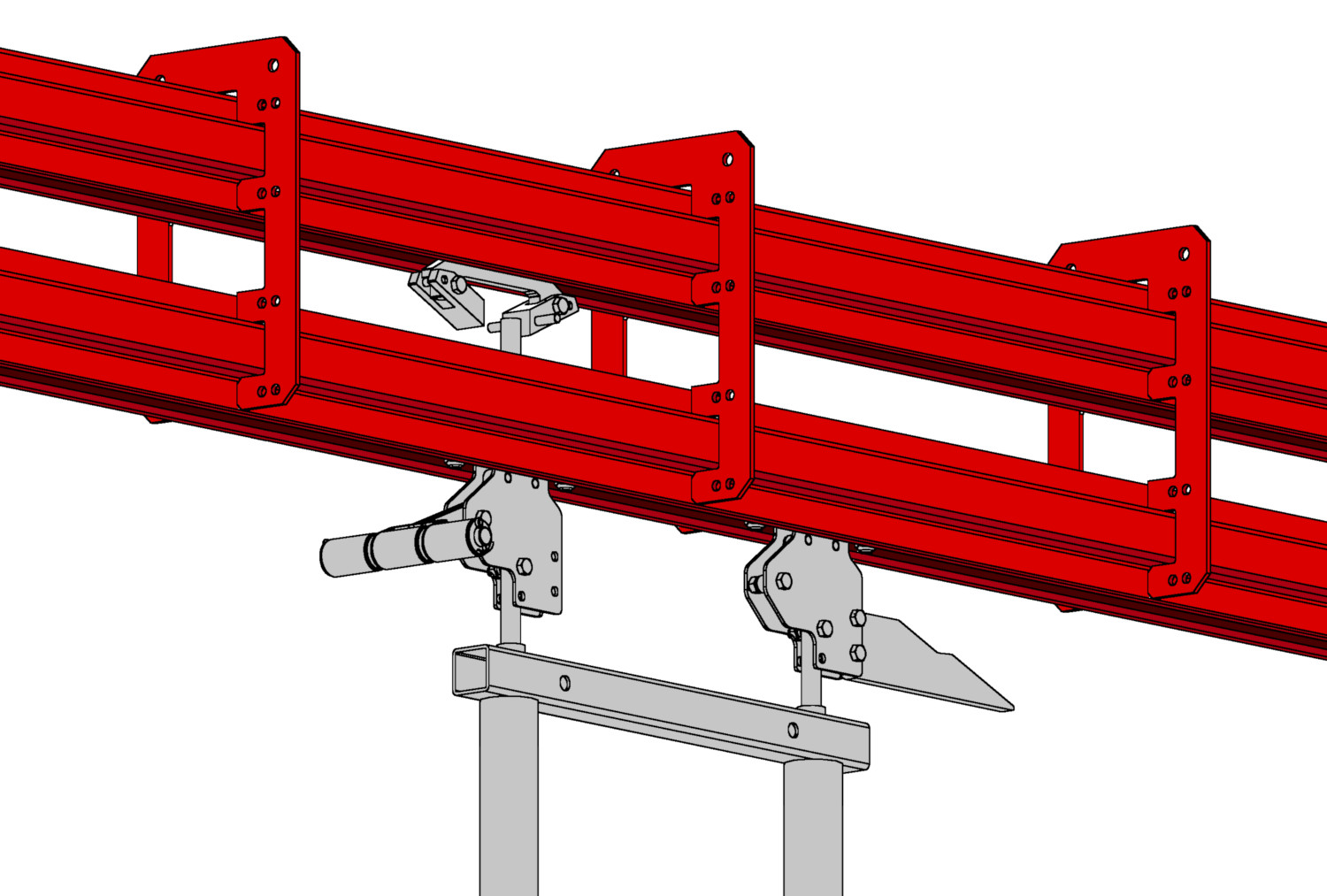

Double rail / Power & Free

The double rail overhead conveyor consists of two overlapping tracks. A biplanar chain runs in the upper track, which does not directly support the loads, but only transmits movement to the trolleys.

Pusher units are attached to the chain, which allow it to engage and drive the trolleys. The trolleys support the loads and slide freely in the lower track.

Due to the flexibility of this system, the trolleys can be released or taken back by the moving chain.

Double rail system allows to:

- Direct carts to different courses

- Manage multiple processing lines on one plant

- Run trolleys at different speeds by diverting them to a different line

- Stop some parts while leaving others in motion

- Create stacking zones to allow parts to station for a set time

- Increase the maximum weights that can be handled

Would you like to learn more about the double rail?